Tel:86-563-4308666

Fax:86-563-4308666

Address: Heli Industrial Development Zone,Ningguo City, Anhui Province

E-mail:webmaster @chinazhengxing.com

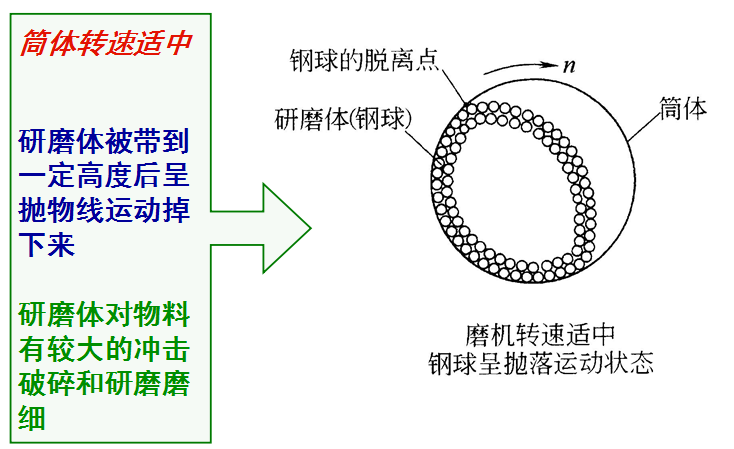

(1) the working principle of ball mill

Grinding ball mill barrel rotates, consideration on the lining board attached to the cylinder with the cylinder rotary. When grinding medium to a certain height after free fall due to gravity, material smash the ground. At the same time the grinding body in addition to the rising and falling movement in grinding, also can produce sliding, rolling, thereby the material inside the mill grinding mill.

Within the medium speed ball mill, the dominant role of grinding coal is crushed. Coal was holding between two grinding medium surface due to the mutual reaction extrusion coal broken. In high-speed hammer mill and fan mill impact is the main role.

Grinding is rely on coal and grinding medium, the relative friction pressure on the grinding body at the same time and make the coal crushing, in high speed, medium speed, ball mill have this effect.

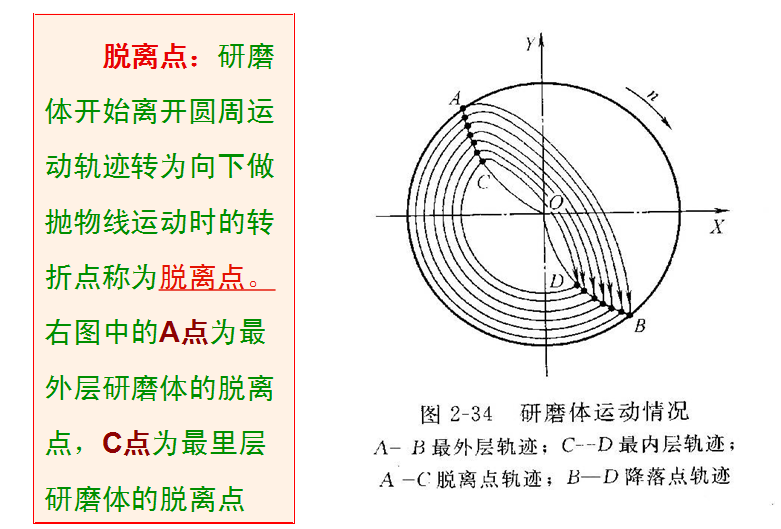

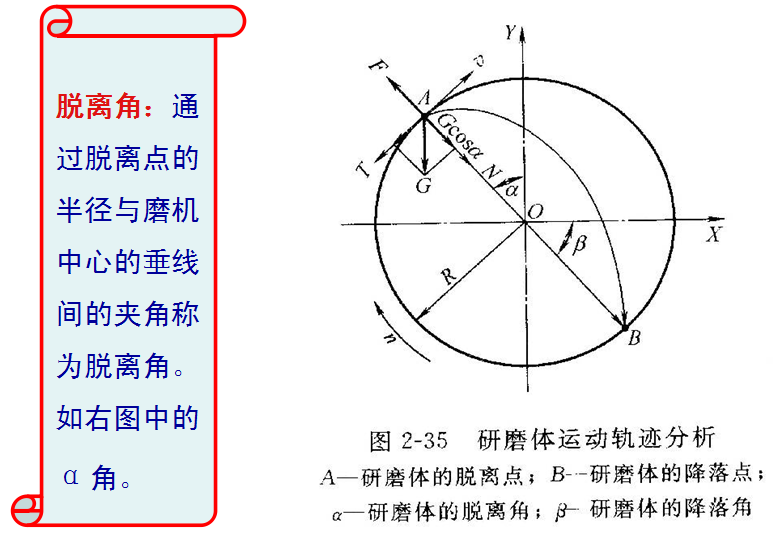

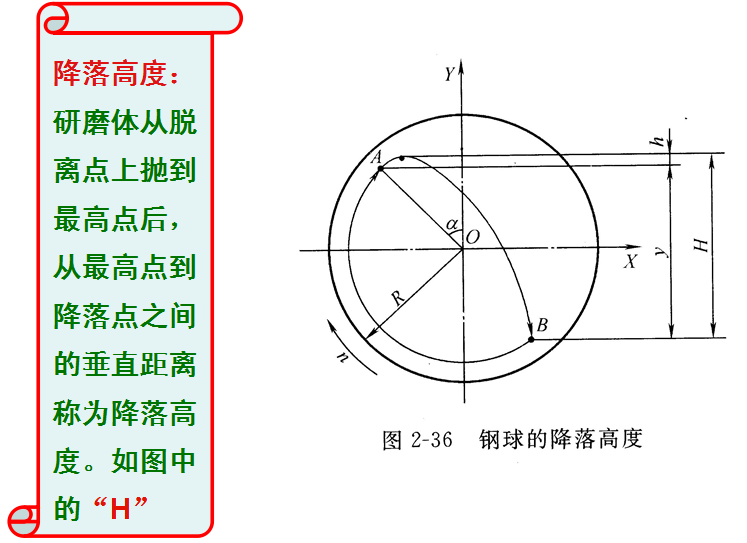

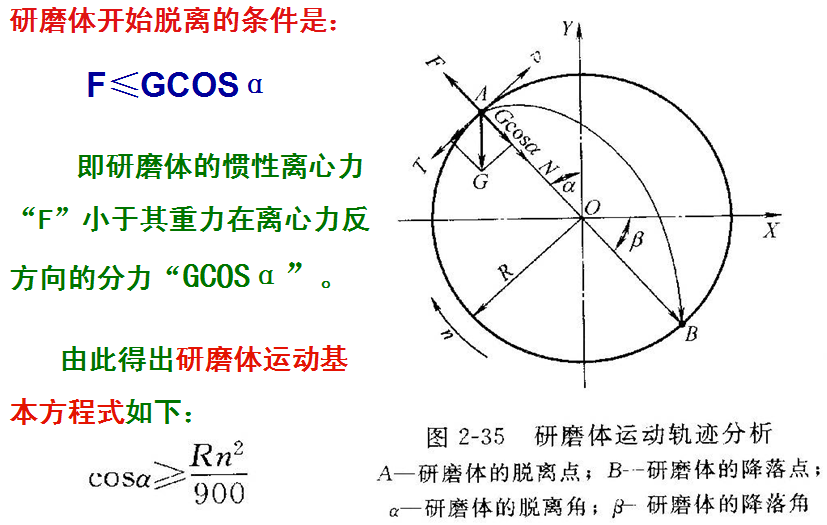

(2) grinding body motions: see below

The meaning of the basic equations of grinding body: grinding medium from the Angle of land (or height) associated with cylinder speed and radius of grinding medium is, and has nothing to do with the quality of grinding medium.

Practice shows that: when a near the wall of grinding medium from the Angle of 54 ° 44 ', grinding medium has the largest land height, which has the most crushing force.

(4) mill speed

Critical speed (n.) : the outermost grinding medium with cylinder just as the speed of the circular motion as the critical speed. Arrived at cylinder peak namely, grinding medium equals the centrifugal force and gravity, from the Angle of 0 °, namely

The outermost layer of grinding medium R D for the mill cylinder. The following conclusions, simplified

I.e., n. D = 42.4 /).

Theory of appropriate speed (ng) : landed the grinding medium maximum height of mill speed is the theory of optimum speed.

Mentioned earlier, when the alpha is 54 ° 44 ', the outermost layer of grinding medium landing height, the largest of crushing capacity is the largest. Alpha for 54 ° 44 'into the following formula:

I.e., ng D = 32.2 /).

Actual working speed (n) : generally divided into the following three conditions:

When D > 2.0 m, n = 32.2 D /). 0.2 D.

When 1.8 m < D 2.0 m or less, the D/n = 32.2).

When D 1.8 m or less, n = 32.2 D /). + (1 ~ 1.5)

The theory of rotational speed ratio (ø) : grinding machine is suitable for rotating speed and the ratio of the critical speed is the speed ratio of the mill. Ø = 0.76

(3) the grinding medium

(1) the effect of grinding medium: the material break within the feed mill, grinding fine.

(2) the kinds of grinding medium: steel ball, steel section and steel bar

A, steel ball, steel ball point contact with the material in the process of grinding, the material has a greater impact, generally used for coarse grinding mill.

B, steel section: grinding with line contact materials, grinding effect is strong, is generally used in fine grinding.

C, steel rods: wet grinding commonly used a kind of grinding medium.

Little ball optimization of train of thought, in view of the ball mill coal pulverizer is (crushing and grinding) and optimization measures are put forward

(1) the ball less saving energy

Grinding ball mill is the main power consumption equipment weight and the weight, the weight of coal proportion is very small. Little ball, it is to point to reduce the weight of steel ball.

Determine indicators: the electrical coal mill table, ammeter, coal mill running time

(2) ensure that the output and pulverized coal fineness of the five measures

(1) the reasonable proportion. Steel ball diameter of 20 ~ 70 all have. Gradation change will change the export coal mill kinds of pulverized coal particle diameter, through the user requirements for pulverized coal fineness, find out an optimal gradation, users need to share of the pulverized coal particle size is the largest, thus reducing the powder quantity, reduce the invalid loops.

(2) reduce the average diameter of steel ball, improve the ability of crushing and grinding.

The same weight 18 tons of steel ball, the number of different diameter when compared with surface area:

The diameter of steel ball number of steel ball surface area

30 163235 461.5

40, 68865 346.15

50 35256 276.9

Under the same conditions, from the height of the ball (land) is superior to the ball, therefore, to increase the number of balls can increase the crushing and grinding of steel ball.

(3) steel ball hierarchical control technology.

The ball in the mill by the import to export from big to small distribution, and in the process of pulverized coal, as it is difficult to grind to the export of coal mill.

Through a variety of steel ball wear ratio and speed control, a certain amount is larger ball exports coal mill. Distribution is more reasonable.

(4) wear resistant steel ball technology. By increasing the effective components and scientific processing technology, to control the ball hardness, wear resistance, broken rate, both inside and outside evenness (internal and external uniform wear resistance and hardness) makes the best ratio of steel ball is not easy to change.

Due to the use of more number of balls, also need steel ball abrasion.

5. Adjust the ratio of added technology.

Output of pulverized coal in use after a certain period of time, according to the index case, need to add the steel ball. Users need to make an assessment of output and pulverized coal index, manufacturers add quantity and proportion for the reasonable design according to user needs.

Mix is changed the traditional increase ball. This is the need of control ratio.

(3) the impact on the coal mill lining board and judgement index

(1) the impact of the extensive use of ball reduces the transform plate. According to the theoretical calculation, the impact of the transform of steel plate is close to the weight of the ball. Ball impact obviously smaller.

Diameter of steel ball weight of 30 to 40 42% by weight of the steel ball diameter, the average diameter of 30, 14 tons of steel ball number is 126961, and 18 tons of number average diameter of steel ball 40 to 68865, assuming all steel ball and the impact of the lining board equal opportunity, impact wear is proportional to the weight, the optimized steel ball impact liner wear is still less.

(2) increase in the amount of coal in the mill effectively reduced the steel ball and the impact of the lining board and grinding, the opportunity to increase the chance of the steel ball contact with coal.

Coal mill in the effective space is limited, in the same mill, controlled by the resistance of the steel ball load down, save coal quantity increase, ball ratio increase footprint reduction, save coal space increases. Storage with increased coal can increase the steel ball mill coal pulverized coal crushing and grinding opportunity, can improve the uniformity of pulverized coal, improve the quality of coal.

Judgement index: coal feeder average operating current or load frequency.

(3) determine the indicators

Steel ball impact to mill lining board has noticeable noise, when the impact to reduce, the coal mill barrel can significantly reduce the noise.

Energy saving, noise reduction, to reduce the consumption

Extend the life of the lining board, the reduction of steel ball added labor intensity

Energy saving

Due to the steel ball weight reduced by 20% ~ 30%, will reduce the coal mill power consumption by more than 20%. The electricity saving cost will pay one-time ball update cost.

Reduce the consumption of ball

Wear-resistant steel ball running the ball within coal consumption can be reduced to 70 g/t, is almost a third of the existing steel ball consumption, although the price of steel ball is two times more than ordinary steel ball, but not increase the total cost of operation consumption of steel ball.

The noise reduction

The noise is occupational safety management system, strict control of index reduce noise to improve working conditions.

Extend the life of the lining board

Commitment, in the case of normal use, the service life of lining board will not shorten, existing can still achieve the repair cycle, maybe even longer.

Reduce the steel ball to add the intensity of labor

Because do not need frequent add steel ball, reduce the operator labor intensity.

Address: Heli Industrial Development Zone, Ningguo City, Anhui Province

Tel:86-563-4308666

Fax:86-563-4308198

E-mail:webmaster@chinazhengxing.com

webapp